Cleanrooms

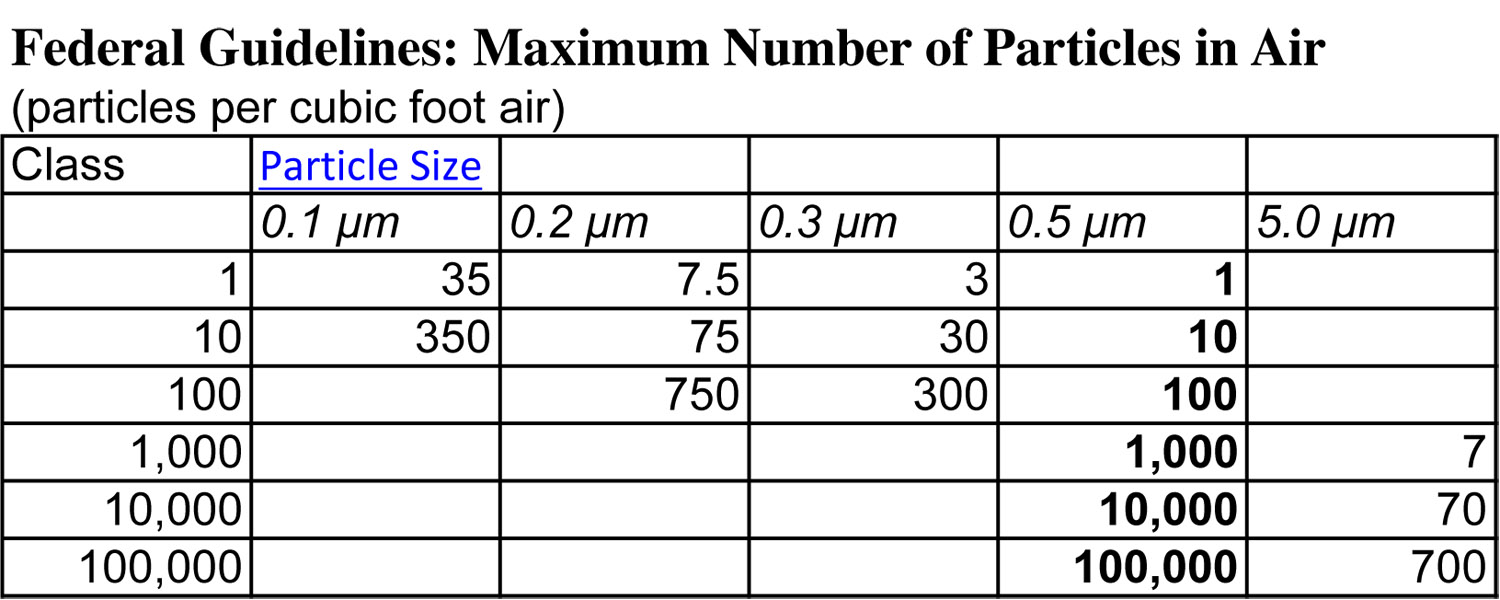

Cleanrooms have various purposes that can be highly beneficial for critical applications, such as laboratories, pharmaceutical companies and electronics manufacturing. Cleanrooms do just what their name implies they remain clean. They have special filtration systems, air exchange rates, control, and humidity that keep out dust, debris, bacteria and any other small particles that could contaminate equipment or laboratories. These filtration systems vary depending on need and can range from class 1 to class 100,000. Class 1 having the least amount of particles per cubic foot.

Typical office building air contains from 500,000 to 1,000,000 particles (0.5 microns or larger) per cubic foot of air. That means in order to reduce a space from 500,000 to 1, an incredible amount of control needs to be available over the space. Most Cleanrooms typically maintain 70 degree temperature with a constant humidity, although occasionally a different temperature is required. The air exchange rate is an important aspect of a cleanroom. Typically an air conditioner changes out the air in a room .5 to 2 times per hour. In a cleanroom the air needs to be exchanged anywhere from 5-600 times depending on the circumstance.

In the situations where a cleanroom is needed a simple miscalculation can lead to contamination with long amounts of downtime and money lost. This means that the utmost controls needs to be available for every aspect of the air in a room. It is not just about humidity, temperature, air flow, air exchange, or filtration but about ALL of them. It is important to work with someone that is highly experienced with cleanrooms. With the money and product that is at risk there is no reason to take a chance with someone who has never done it before.