Southington YMCA

SOUTHINGTON YMCA

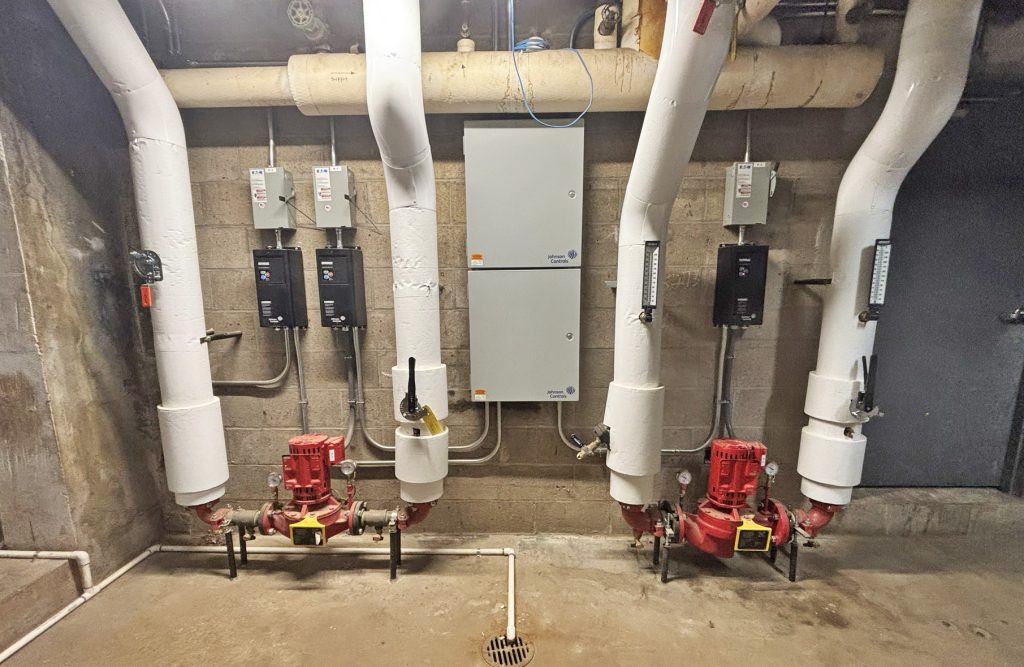

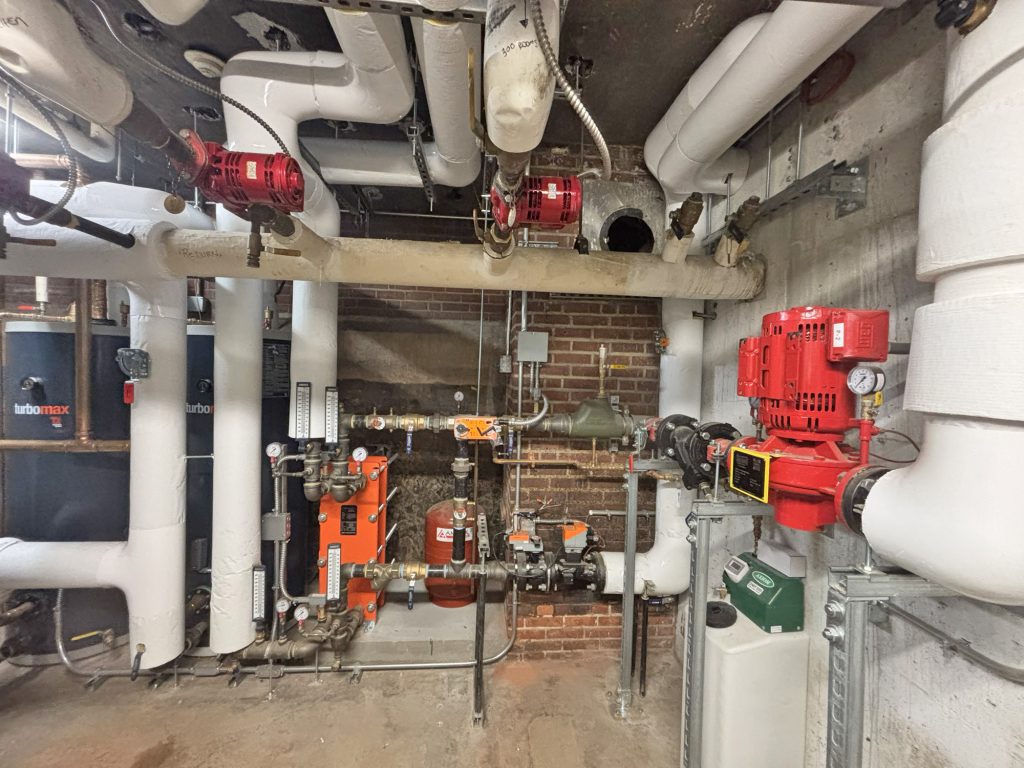

Controlled Air installed a Yanmar cogeneration system in coordination with a new boiler plant and domestic hot water production to reduce energy costs for the Southington YMCA. Our work included the mechanical demolition and removal of existing oil tanks, boilers, domestic hot water tanks, and remaining equipment from the previous co-generation system. At the heart of the new system, we furnished and installed two 35kW Yanmar high-performance CHP systems with the ability to produce a total of 70kw of power for the facility and hot water to be used in the production of heat and domestic hot water. These systems incorporate a heat exchanger, with a glycol-based system for heat recovery. To increase the efficiency of the new system, we replaced the old, worn-out boilers with two high-efficiency Patterson Kelley Storm ST-2000, 2,000,000 BTU, gas-fired condensing boilers equipped with a BACnet interface.

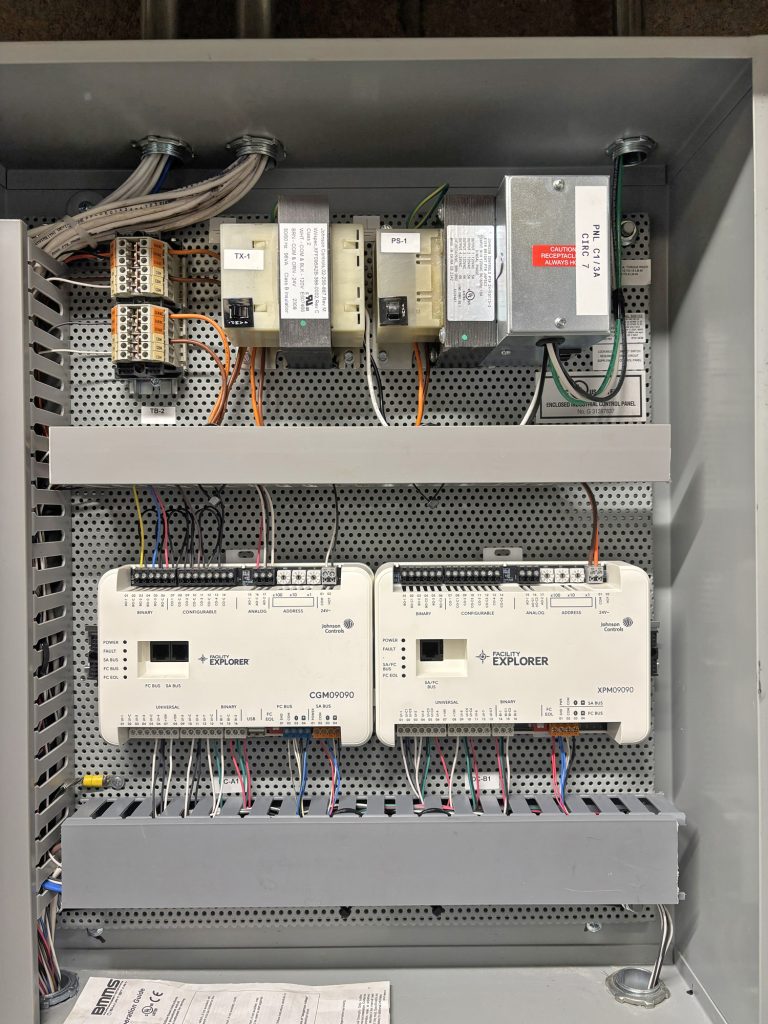

These new boilers will significantly increase efficiency, while working in conjunction with the Yanmar CHPs to produce domestic hot water and heating at the most efficient rate. We also installed new circulating pumps, associated pump specialties, and the necessary gas piping to the new equipment. To control the system, we installed a new Johnson Controls BMS system to operate the heat exchanger, radiators, boilers, and the cogeneration system.

Yanmar Cogeneration Systems offer significant advantages. By simultaneously generating both electricity and heat, they achieve high energy efficiency, reducing energy costs and environmental impact. The YMCA can lower their reliance on the grid, improving energy security and reducing vulnerability to price fluctuations.